Monitoring Rail Track Silica Levels

When rail track is damaged or needs replacing, the ballast surrounding the track is disturbed which can release silica - a harmful substance to humans if inhaled. Using the world’s first live silica monitor, this project helped provide The Central Rail Systems Alliance (CRSA) with live reporting to assess the real-time safety of their activities.

- Customer Name

- Central Rail Systems Alliance (CRSA)

- Duration

- 12 hour long period, between 25th - 27th of March

- Products (Inc Quantity)

-

Trolex Air XS, the world-first Respirable Crystalline Silica (RCS) monitor

Intro

The Central Rail Systems Alliance (CRSA) routinely check their network of track for weaknesses, replacing damaged track and the accompanying ballast as necessary.

During the process individuals working in the area are required to wear appropriate Respiratory Protective Equipment (RPE) to protect themselves against inhaling harmful substances, particles or contaminants in the air.

Given the extensive unearthing taking place when replacing track, high levels of Respirable Crystalline Silica (RCS) can be released, exposing workers in the area to potentially harmful particles.

The Challenge

The challenge was to measure the level of RCS and accompanying dust being released into the atmosphere during the unearthing process of 425m rail, and ascertain the level of risk associated for those working in the immediate and surrounding environments. The CRSA took a proactive approach to uncovering the levels of RCS involved in such a process, to protect the health of their individuals and raise awareness for others in the market to create a blueprint for a safer working environment moving forward.

Considering the eventual recording of RCS levels, it would then be necessary to contextualise the risks of RCS exposure so the CRSA could determine whether further implementations should be invoked to protect the individual health of workers.

The Solution

To uncover the live exposure levels during the replacement process, the world first real-time RCS monitor – the Trolex Air XS from Sunbelt Rentals – was chosen to record levels over a period of 12 hours between the 25th to 27th March 2023. First the Air XS recorded the levels of dust emitted during the unearthing process, which is valuable data on its own, but the RCS levels were also monitored in real-time and reported back in a live data set so work could be halted if recorded silica levels reached dangerous heights.

In order to make sure accurate levels were recorded, the Air XS’ portability was leaned upon so it could be manoeuvred around the site in-line with project progress, so that working scenarios can be accurately represented in the data set.

Using light refraction properties unique to silica, Air XS detects every particle flowing through it during the works, and then analyses its size, shape and refractive qualities to provide a live onscreen value of airborne silica. Key features of the Air XS include:

- On-device display of RCS measurement in mg/m2 or total particles counted per litre of air sampled. Rolling averaging periods are based on 15-minute, 1, 4, 8, and 12-hour patterns.

- On device warnings and alarms based on custom trigger thresholds.

- Data logging for download and post analysis using the Trolex BreathXS software.

The Result

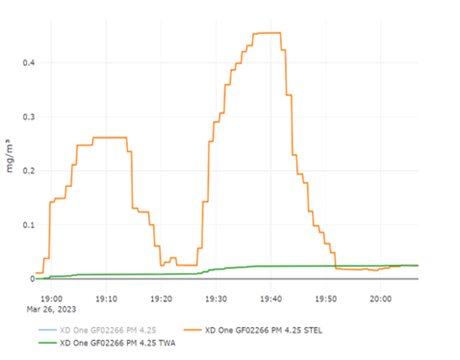

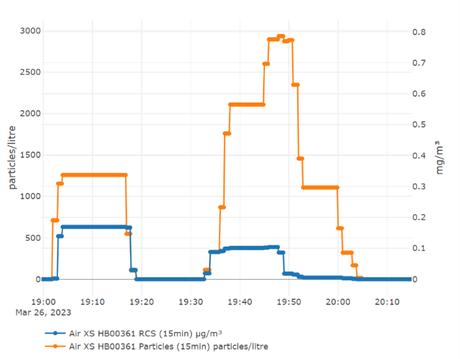

Over the course of the 12-hour recording period, the Trolex Air XS monitor measured and reported high levels of silica being released, with the exposure level reaching up to 0.75mg/m3 for a short peak period, seven times the 0.1mg/m3 recommended levels as outlined by the HSE. Despite this, these peak levels were not active for long periods of time, instead the average exposure level for the site activity was at 0.4mg/m3, but this still sits significantly higher than the recommended levels for human exposure.

During the exposure testing, a subsequent Trolex unit was placed in the surrounding areas to the site activity which still recorded a peak of 0.45mg/m3 of dust exposure, and an average of 0.2mg/m3. Meaning those who are nearby, without a perceived risk of needing RPE before now, would’ve likely have still been exposed to higher than recommended levels.

In analysing the data recorded by the Trolex Air XS over the 12-hour period it became clear that there is a significantly higher level of silica released when unearthing railway track and the accompanying ballast, exposing both workers and surrounding people to potentially harmful levels of silica, particularly at peak levels of activity but also with lower levels of activity as well.

Considering that only dust exposure has been monitored during such activities in the past and silica has not been included in trials, this has given the CRSA a clear breakdown of their worker exposure levels in order for them to make the safest and most health-conscious decisions and other preventative measures are concerned in order to protect their workforce and create a blueprint for a safer working environment moving forward.

Figure 1 - Silica Exposure Levels On Site. Figure 2 - Dust Exposure Levels On Site.

The team at Sunbelt were really informative from start to finish and took the time to fully demonstrate the unit’s capabilities and understand what works were going to be taking place. We have completed trials prior, however this is the only unit where it is measuring Silica and not just general dust levels. We gained the knowledge that the exposure levels were actually higher than we anticipated with even low-level ballast disturbance. This has been a fundamental aid in helping us understand what levels of Silica emissions are present.”Madeline Dunn - Health & Safety Advisor, Central Rail Systems Alliance (CRSA)

Want to know how Sunbelt Rentals could help your project? Contact us below:

Open your account online within 24 hours

Open your account online within 24 hours  Nationwide, next day delivery available

Nationwide, next day delivery available  Over 200 locations near you

Over 200 locations near you